NON FERROUS METALS SUPPLIER IN INDIA

We are the most prominent Non Ferrous Metals Supplier to the Steel Manufacturing IndustryWe supply best quality Silicon Metal | Manganese Metal | Magnesium Ingots

Being one of the most prominent traders in the Steel Manufacturing Industry, we take the pride of commanding the supply line of Non Ferrous Metals.

Our products are distinguished by their higher grade and quality, that is combined with our hands-on experience; thereby ensuring that our corporate customers always receive the best.

We supply bulk shipments of various Base Metals, Minor Metals, Ferro Alloys, etc. Such as Lead, Nickel, Molybdenum, Zinc, Chromium, Silicon, etc. all over the World.

With our large supply ability we can meet all major requirements of the following Metals, those are majorly used in steel plants and can supply all grades of these:

- Silicon Metal

- Manganese Metal Flakes/Briquettes

- Magnesium Ingots

Silicon Metal

Manganese Metal Flakes/Briquettes

Magnesium Ingots

Silicon Metal

We are the suppliers, super stockiest & indenting agents of Silicon Metal.

SILICON, a tetravalent metalloid, is a chemical element with the symbol Si and atomic number 14.

Elemental silicon also has a large impact on the modern world economy. Most part of free silicon is used in the steel refining, aluminum-casting, and fine chemical industries (often to make fumed silica). A relatively small portion of very highly purified silicon is used to manufacture semiconductors for electronics industry (< 10%). Because of wide use of silicon in integrated circuits (IC’s), the development of most computers, electronic devices and a great deal of modern technology depends on it.

PROPERTIES:

Silicon is solid at room temperature, with relatively high melting and boiling points of 1414 and 3265 degrees Celsius respectively. It has a greater density in a liquid state than a solid state.

With a relatively high thermal conductivity of 149 W•m−1•K−1, silicon conducts heat very well and as a result it is not often used for insulation purpose. In its crystalline form, pure silicon has a gray color and a metallic luster.

Most metallurgical silicon metal is used as an alloying agent in the aluminum industry due to its ability to increase the strength of aluminum. Demand of silicon in the aluminum industry has grown rapidly in recent years due to increased usage of aluminum in structural engineering, aircraft manufacturing and automobile industry. Aluminum alloys are lighter and more resistant to corrosion than carbon-steel and can be made by addition of metals such as copper, zinc, magnesium, manganese as well as silicon.

METALLURGICAL GRADE & PRODUCTION:

Elemental silicon not alloyed with significant quantities of other elements, and usually > 95%, is often referred to loosely as silicon metal. Metallurgical grade silicon is commercially prepared by the reaction of high-purity silica with wood, charcoal, and coal in an electric arc furnace using carbon electrodes.

It being the carbo thermic reaction of silica (quartz) in an electric arc furnace using carbon electrodes where the temperature in the main reaction zone of temperatures exceeds 1800ºC.

At temperatures over 1,900 °C (3,450 °F), the carbon in the aforementioned materials and the silicon undergo the chemical reaction

SiO2 + 2 C → Si + 2 CO.

Liquid silicon collects in the bottom of the furnace, which is then drained and cooled. The silicon produced this manner is called metallurgical grade silicon and is at least 98% pure.

Using this method, silicon carbide (SiC) may also form from an excess of carbon in one or both of the following ways:

SiO2 + C → SiO + CO or SiO + 2 C → SiC + CO.

However, provided the concentration of SiO2 is kept high, the silicon carbide can be eliminated by the chemical reaction

2 SiC + SiO2 → 3 Si + 2 CO

As noted above, metallurgical grade silicon “metal” has its primary use in the aluminum casting industry to make aluminum-silicon alloy parts. The remainder (about 45%) is used by the chemical industry, where it is primarily employed to make fumed silica.

APPLICATIONS:

Adding Silicon Metal to aluminium alloys makes them strong and light. As a result they are increasingly used in the automotive industry to replace heavier cast iron components. This allows weight reductions, a reduction in fuel consumption, increased efficiencies and subsequent benefits to the environment by reducing the greenhouse gas emissions and conserving fossil fuels.

There is increasing demand for Silicon Metal from the solar power generating industry where solar panels are made from silicon, which use the sun’s energy to produce domestic and industrial electricity. Silicon based polymers are also used as alternatives to hydrocarbon based products. They can appear in many every day products such as lubricants, greases, resins, skin and hair products. A more well known use of silicon is silicon chips, produced from semi-conductor grade silicon they are components in many every day electronic devices.

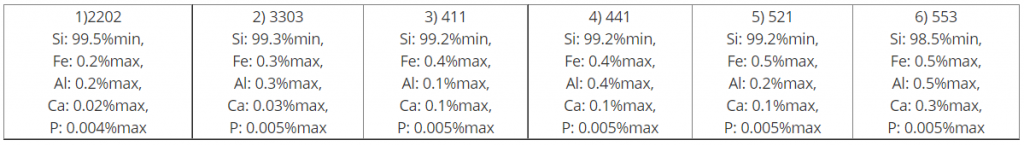

Type: 2202, 3303, 3205, 411, 521, 441, 553

Size: 10-100 mm

Manganese Metal

Manganese is a chemical element with symbol Mn and atomic number 25. It is not found as a free element in nature; it is often found in combination with iron, and in many minerals. Electrolytic Manganese is a metal with important industrial metal alloy uses, particularly in stainless steels.

We are the LEADING suppliers of Electrolytic Manganese Metal Flakes /Briquettes.

Specification:

Magnesium Ingots

Magnesium is the ninth most abundant element in the universe. It is synthesized in large, aging stars from the sequential addition of three

helium nuclei to a carbon nucleus.

We are the LEADING suppliers of Magnesium Ingots.

Magnesium Ingots are acid washed.

It is widely used in the manufacturing of Ductile Iron Pipes. Ingots of several sizes are produced based on application.

Specification: