TUNGSTEN CARBIDE RING SUPPLIER IN INDIA

TUNGSTEN CARBIDE ROLL SUPPLIER IN INDIA

TUNGSTEN CARBIDE RING

Tungsten Carbide Ring (roll) or TC ring is a tool material which contains Tungsten Carbide and Cobalt. Tungsten carbide is the most scratch-resistant metal known to man. Tungsten carbide by itself is a powder. It requires a binder, like nickel, to hold it all together to form a shape. Tungsten Carbide rolls are used in the manufacturing of mill rolls & wire flattening for extended life in applications where long rolling campaigns are required. Their extreme hardness makes them suitable for wire rods finishing blocks and some shaping applications

The following are some of the characteristics of Tungsten Carbide:

- high hardness

- wear resistance

- long service life

- high efficiency

Siddharth Maloo Group is one of the top Tungsten Carbide Ring Supplier in India

ABOUT TUNGSTEN CARBIDE

- Structural strength : Binding tungsten and carbon, it forms an extremely dense crystal structure called hexagonal crystal, whose Young’s modulus is approximately 550 GPa, which is nearly two times that of steel.

- High Hardness : The Mohs’ hardness of tungsten carbide is “9.” It boasts a level of hardness second to diamond.

High strength at high temperature : Since it has high strength at high temperature and low thermal expansion coefficient, it is an optimal raw material for cutting tools to be used in a high-temperature and high- speed environment.

- High resistance to corrosion : Tungsten carbide is an extremely stable substance, and it does not oxidize at normal temperatures in air. In addition, it is not likely to form a solid solution with various elements, and keeps stable characteristics even in severe environments.

Resistance to oxidation : Oxidation occurs at approximately 300°C and reaction occurs rapidly at approximately 700°C to form an oxide (WO3) when its powder is heated in an oxygen-containing atmosphere.

- Chemical resistance : Although it does not dissolve in water, hydrochloric acid or sulphuric acid, it dissolves in nitric acid.

Reactivity : Reacts with chlorine at 400°C or higher. Reacts with fluorine at 18°C.

TUNGSTEN CARBIDE RING APPLICATION

Tungsten Carbide Rings are used in the manufacture of mill rolls & wire flattening for extended life in applications where long rolling campaigns are required. Their extreme hardness makes them suitable for wire rods finishing blocks and some shaping applications. Tungsten carbide roll required by steel mills. It is mainly divided into four categories: high- speed wire rod roll, new generation high speed wire rod hot-rolled roll, new generation high-speed wire rod review roll, and cold-rolled three-dimensional roll.

- The roll has good thermal conductivity, high wear resistance, corrosion resistance, and good general performance. It can obviously reduce the depth and width of hot cracks in the groove during rolling, and reduce the risk of roll cracking.

- The new generation of high-speed wire rod hot mill roll has higher impact resistance, thermal fatigue resistance, and high wear resistance compared with high-speed wire hot rolling roll. It is suitable for high-speed wire rod rolling with speed over 100 m / s.

- The new generation of high-speed wire rod composite roll can greatly reduce the number of grooves changing and roll changing, reduce the labour intensity, improve the labour production efficiency, improve the surface quality of rolled products, and the percentage of finished products, so as to obtain remarkable economic benefits.

- Cold rolled ribbed still bar is rolled by cold rolling three-dimensional roller. The surface appearance of the steel bar is beautiful, the dimension precision is high, and the rib mark is clear. At the same time, the performance of the ribbed steel bar is changed and the strength is improved. The rolling capacity is 800-1500 tons, which is 20-50 times

higher than that of common tool steel. - TC roller can be used repeatedly, which can greatly reduce the cost and significantly improve efficiency and efficiency. In addition, we also

provides roller maintenance services to customers.

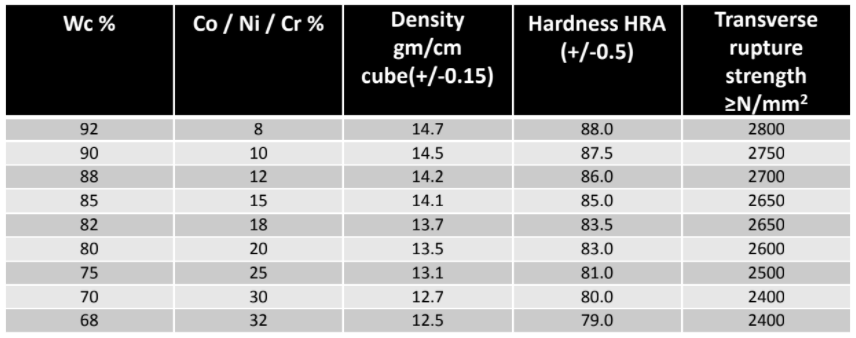

VARIOUS TYPES OF

TUNGSTEN

CARBIDE RINGS

WITH CHEMICAL

COMPOSITION

AND PHYSICAL

PROPERTIES

Wc % | Co / Ni / Cr % | Density gm/cm cube(+/-0.15) | Hardness HRA (+/-0.5) | Transverse rupture strength |

|

|

|

| ≥N/mm2 |

92 | 8 | 14.7 | 88.0 | 2800 |

90 | 10 | 14.5 | 87.5 | 2750 |

88 | 12 | 14.2 | 86.0 | 2700 |

85 | 15 | 14.1 | 85.0 | 2650 |

82 | 18 | 13.7 | 83.5 | 2650 |

80 | 20 | 13.5 | 83.0 | 2600 |

75 | 25 | 13.1 | 81.0 | 2500 |

70 | 30 | 12.7 | 80.0 | 2400 |

68 | 32 | 12.5 | 79.0 | 2400 |

WHY US

- We are experienced veteran Tungsten Carbide Ring Supplier to Steel Plants in India

- Out team consists of Engineers and Tech Support which ensures doing business with us really

customer friendly. - We are provider of best quality Rolls with laser sharp precision

- Products are manufactured in facilities consisting of auto-presses, presses, Heat treatment Furnaces, wire cutting machine, CNC Machines, CMM,EDMs. We produce accurate products as per customers requirement.

- We have a strict quality control policy in place to ensure quality inspection process before every shipment.

- Integrity, Honesty and Loyalty has always won our Customer’s trust.

INSPECTION PROCESS

- Raw material inspection by Inductive Coupled Plasma Emission Spectrometer(ICP)

- In process inspection by experienced and qualified inspectors

- Internal Crack checking by Ultrasonic fault detector

- Dynamic balance checking by digital method

- Final dimensional inspection by Co-ordinate Measuring Machine

- Final Metallurgical structural inspection by Metallographic Microscope

- Hardness inspection by Digital hardness checking Method before dispatch